Porsche's New Braided Carbonfibre Wheels Could Be The Coolest Rims We've Ever Seen

Porsche has revealed an incredibly fancy new type of wheel, using braided carbonfibre as a key part of its construction.

Made from a stunning carbonfibre-reinforced polymer, the new rims will only grace the wheel arches of the 911 Turbo S Exclusive Series (for now), but in choosing to up its wheel game Porsche has become the first car maker to offer braiding technology in this way, making the wheels’ structure denser and more compact – thus more rigid. Porsche says they are 20 per cent stronger than its alloys.

Per set of four, they cut 8.5kg from the car’s unsprung weight – that’s a handy 20 per cent reduction against the already lightweight alloy options. The process itself is hugely complex, so Porsche’s simplified description is the one we’ll use:

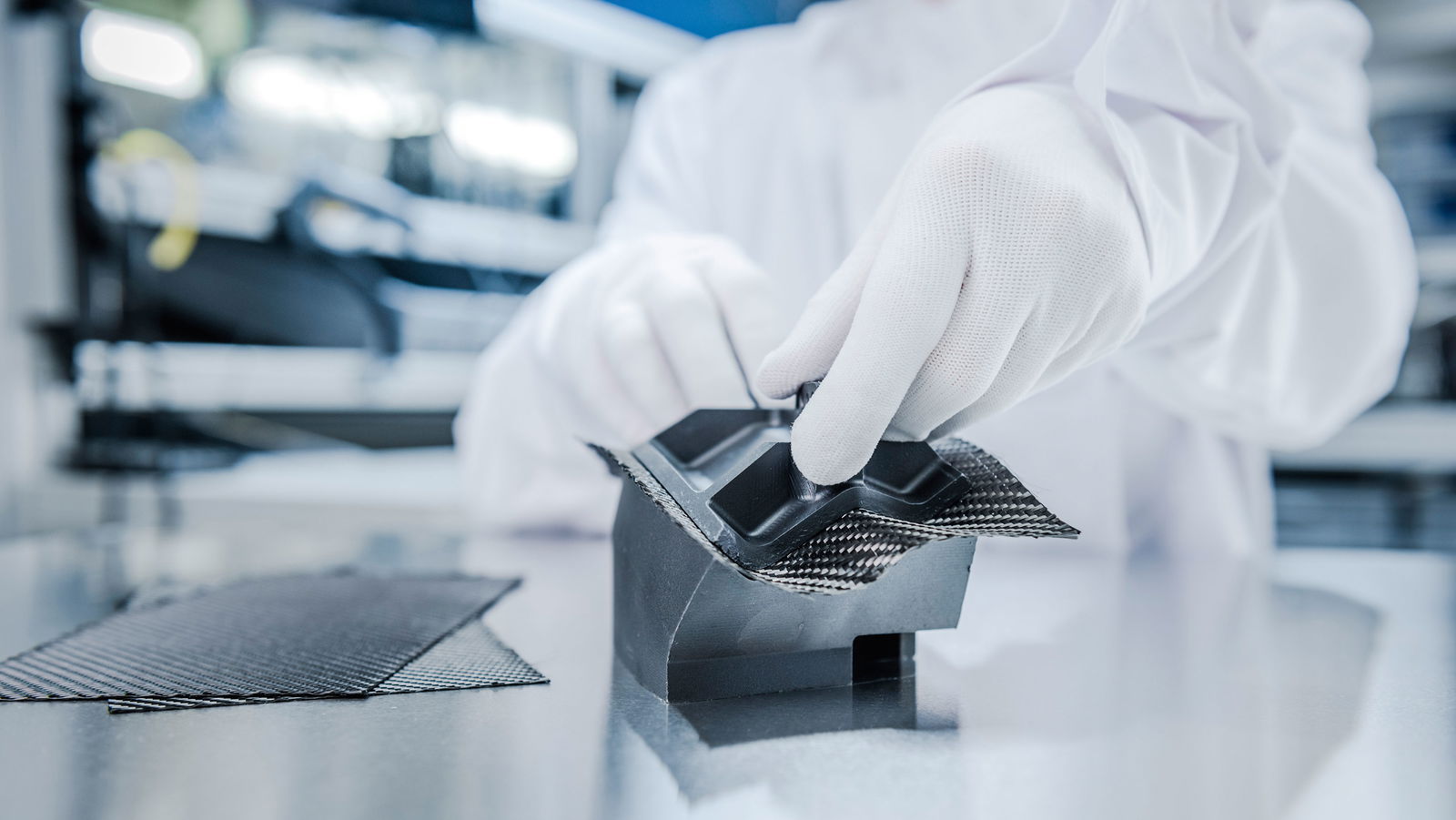

“Manufactured entirely from carbonfibre reinforced polymer (CFRP), the wheel is essentially comprised of two components. The wheel centre is made from carbonfibre fabric. This involves cutting and assembling over 200 individual components.

“The second component is the rim base made from braided carbonfibre by what is currently the world’s largest carbonfibre braiding machine with a diameter of approximately nine metres. The wheel centre is then braided into the rim base.

“The assembled wheel is impregnated with resin and pre-hardened at high pressure and high temperatures. The finished wheel is hardened at high temperatures followed by a long cooling process. The central lock is then inserted into the finished wheel and the wheel is protected with clear lacquer.”

The amount of carbonfibre that goes into each wheel is incredible. In total each uses 18 kilometres of actual fibre, or the same as eight square metres of carbonfibre fabric. They will only be made in 9Jx20 and 11.5Jx20 sizes, to fit the current 911 Turbo series. The price? A mere €15,232 per set, in Germany. For God’s sake, don’t go anywhere near kerbs.

The Turbo S Exclusive Series uses the familiar 3.8-litre twin-turbo flat-six, in this trim muscling 599bhp and 553lb ft to all four wheels. Zero to 62mph is the work of just 2.9 seconds, while 0-100mph takes a bankers 6.3 seconds and 0-124mph a still-brisk 9.6 seconds. Fast as it is, though, that really puts the McLaren 720S’s 7.8-second 0-124mph time into perspective…

Comments

[DELETED]

€15,232? Absolute bargain compared to Porsche design glasses!

Gimmie gimmie gimmie gimmie Gimmie gimmie gimmie gimmie Gimmie gimmie gimmie gimmie Gimmie gimmie gimmie gimmie Gimmie gimmie gimmie gimmie

I think that Koenigsegg did it better with the wheels on the One:1, but thats just my opinion.

“Vajazzle” ~ blue mountain state

While Ferrari are divising a plan how to fiddle with the production numbers of their “limited” models and get more profits, Porsche are actually innovating.

Just google wheel job vs rimjob and see if its the same thing..

Costs more than my car. When it was new…

From afar they look like Saab badges because of the blue behind the porsche badge.

Cough Cough

Pagination